The tool reducing gadget has a amazing shape, which permits robust machining with a massive amount of slicing, as a result enhancing the processing performance of the tool slicing gadget. the form of rotation tempo and feed of the tool slicing device spindle is larger than that of everyday tool tools, so the maximum favorable lowering quantity may be determined on for every procedure of the device system device.

Contact Now

The device cutting machine has a incredible form, which permits robust machining with a large amount of slicing, as a result improving the processing performance of the device cutting gadget. the variety of rotation tempo and feed of the device cutting system spindle is greater than that of regular gadget gear, so the maximum favorable cutting quantity may be selected for every approach of the tool gadget device.

Contact Now

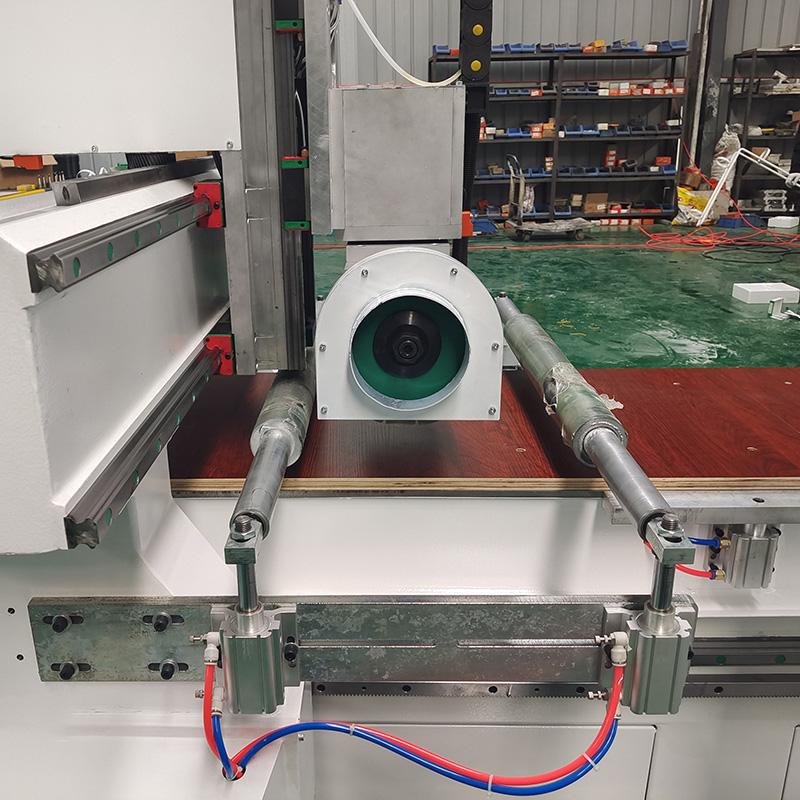

The strain curler is fixed with materials to ensure the accuracy, the control box is smooth and tidy, and the wiring is orderly, which significantly reduces the capability safety hazards.

Contact Now

The tool decreasing device is processed steady with the instructions given in virtual shape. usually, the taking walks way does no longer require manual intervention, which receives rid of the mistake due to the operator. on the equal time as designing and manufacturing the device tool device, many measures have been taken to accumulate immoderate precision and pressure of the mechanical a part of the device lowering device. in addition, the strain tool and form of the knife decreasing device have excessive stress and thermal balance.

Contact Now

The cutter slicing gadget can realize the movement of just about any trajectory and process the workpiece of any shape, and is suitable for the processing of complex unique-fashioned parts.FeaturesThe disc tool changer + sub-mother saw processing center creates an intelligent production process for panel furniture cutting and punching. It is the preferred equipment for the production of customized furniture in the whole house. The main functions are as follows:1. Accurate positioning.

Contact Now

Applicable Relevant to all sorts of stone, metal, jade, crystal, timber, synthetic materials, artificial substances, and so forth.;Utilized in inscriptions, garden engineering, large-scale sculptures, handicraft carvings, domestic ornament, video walls and other industries;Function: embossing, lettering, hollowing out, cutting, seamless splicing, surface remedy, table pinnacle milling, etc. FeaturesThe disc tool changer + sub-mother saw processing center creates an intelligent production process for panel furniture cutting and punching.

Contact Now

The device reducing device is processed in step with the instructions given in digital form. commonly, the running manner does now not require manual intervention, which gets rid of the error due to the operator. at the same time as designing and production the tool tool tool, many measures were taken to build up immoderate precision and strain of the mechanical part of the tool lowering tool. in addition, the stress device and shape of the knife slicing tool have immoderate strain and thermal balance.

Contact Now

The tool slicing device is processed in keeping with the instructions given in digital form. commonly, the operating way does now not require guide intervention, which gets rid of the error due to the operator. whilst designing and manufacturing the tool tool device, many measures had been taken to gather immoderate precision and strain of the mechanical part of the device reducing machine. further, the pressure device and structure of the knife slicing device have excessive pressure and thermal stability.

Contact Now

The tool slicing system has a terrific structure, which allows sturdy machining with a massive quantity of slicing, as a result improving the processing performance of the tool slicing gadget. the form of rotation pace and feed of the device cutting device spindle is bigger than that of everyday tool tools, so the most favorable decreasing quantity may be decided on for every process of the device machine tool.

Contact Now

The tool decreasing device is processed in step with the instructions given in digital form. commonly, the walking way does now not require guide intervention, which gets rid of the mistake because of the operator. on the identical time as designing and manufacturing the device tool tool, many measures were taken to build up excessive precision and pressure of the mechanical part of the tool lowering tool. in addition, the pressure tool and form of the knife cutting tool have immoderate stress and thermal stability.

Contact Now

The machine is prepared with a renovation device with excessive tempo and excessive precision. one machine can deal with a ramification of products. this product is a custom designed industrial mechanical product, and the model is custom designed consistent with the real needs of customers.it is suitable for the manufacturing of cupboard doors, strong wood doorways, pc desks, panel furniture, and so forth.; it may be used for large-region, immoderate-output excessive-density forums, aircraft engraving, slicing. this device is for severa and complex processing.

Contact Now

The tool cutting machine is processed according to the instructions given in digital form. Generally, the working process does not require manual intervention, which eliminates the error caused by the operator. When designing and manufacturing the tool machine tool, many measures have been taken to achieve high precision and rigidity of the mechanical part of the tool cutting machine. In addition, the drive system and structure of the knife cutting machine have high rigidity and thermal stability.

Contact Now

The tool cutting machine has a good structure, which allows robust machining with a huge quantity of slicing, thus improving the processing performance of the tool slicing system. the variety of rotation pace and feed of the tool cutting machine spindle is larger than that of everyday device gear, so the most favorable reducing quantity may be selected for every process of the device gadget tool.

Contact Now

The device cutting gadget has a high-quality form, which lets in strong machining with a massive amount of reducing, as a end result enhancing the processing typical overall performance of the device lowering gadget. the fashion of rotation pace and feed of the device lowering tool spindle is greater than that of everyday system equipment, so the maximum favorable cutting amount can be determined on for every approach of the tool gadget device.

Contact Now

The gadget is prepared with a maintenance gadget with high pace and excessive precision. one system can cope with a selection of merchandise. this product is a customized industrial mechanical product, and the model is custom designed in line with the real wishes of customers.it's miles appropriate for the producing of cabinet doors, solid wooden doors, computer desks, panel furniture, and so forth.; it could be used for massive-area, excessive-output excessive-density boards, aircraft engraving, cutting. this machine is for numerous and complex processing.

Contact Now

It's far suitable for the producing of cupboard doors, robust wood doors, computer desks, panel furniture, and lots of others.; it can be used for big-place, excessive-output high-density forums, plane engraving, slicing, three-D embossing and special procedure operations of strong wood forums. this device is for numerous and complex processing.

Contact Now

Automatic tool setting, setting automatic tool setting instrument, automatic tool setting, good accuracy and high efficiency.The Four Process Cutting Machine is suitable for panel furniture, solid wood furniture, solid wood composite doors, etc.

Contact Now

In the case of single-piece, small batch production, machining with a cutter cutting machine can reduce adjustment, machining and inspection time and save direct production costs. The machining accuracy of the tool cutting machine is stable, which reduces the scrap rate and further reduces the production cost. Therefore, the use of knife cutting machine can obtain good economic benefits.FeaturesThe disc tool changer + sub-mother saw processing center creates an intelligent production process for panel furniture cutting and punching.

Contact Now

The device cutting gadget is processed in line with the instructions given in virtual form. typically, the operating manner does not require guide intervention, which eliminates the mistake caused by the operator. when designing and production the device device tool, many measures were taken to acquire excessive precision and pressure of the mechanical part of the device cutting machine. similarly, the force machine and structure of the knife cutting gadget have excessive stress and thermal stability.

Contact Now

This type of CNC plasma cutting machine for the table gantry structure, the whole machine working table adopts the overall edge structure, with stable and reliable operation, long service life and other characteristics; This model adopts optical axis linear guide and bilateral drive.

Contact Now

The tool cutting machine is processed according to the instructions given in digital form. Generally, the working process does not require manual intervention, which eliminates the error caused by the operator. When designing and manufacturing the tool machine tool, many measures have been taken to achieve high precision and rigidity of the mechanical part of the tool cutting machine. In addition, the drive system and structure of the knife cutting machine have high rigidity and thermal stability.

Contact Now

FeaturesThe disc tool changer + sub-mother saw processing center creates an intelligent production process for panel furniture cutting and punching. It is the preferred equipment for the production of customized furniture in the whole house. The main functions are as follows:1. Accurate positioning. The CNC cutting machine has 6 positioning cylinders, which is fast in positioning and more convenient in changing plates.2. Stable model. All three axes use original linear square rails, which have good stability, long service life and high precision.3.

Contact Now

The saw blade machine can cut the material thicker and faster than the ordinary cutter machine, and the multi-saw blade machine can meet the cutting in various directions.Hotels, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising CompanyFeaturesThe disc tool changer + sub-mother saw processing center creates an intelligent production process for panel furniture cutting and punc

Contact Now

FeaturesThe disc tool changer + sub-mom saw processing center creates an smart production technique for panel fixtures cutting and punching. it's far the desired device for the production of customized furnishings in the entire residence. The primary capabilities are as follows:1. Accurate positioning. The CNC cutting machine has 6 positioning cylinders, which is fast in positioning and more convenient in changing plates.2. Stable model. All three axes use original linear square rails, which have good stability, long service life and high precision.3.

Contact Now